News and articles, Page 4

List of articles

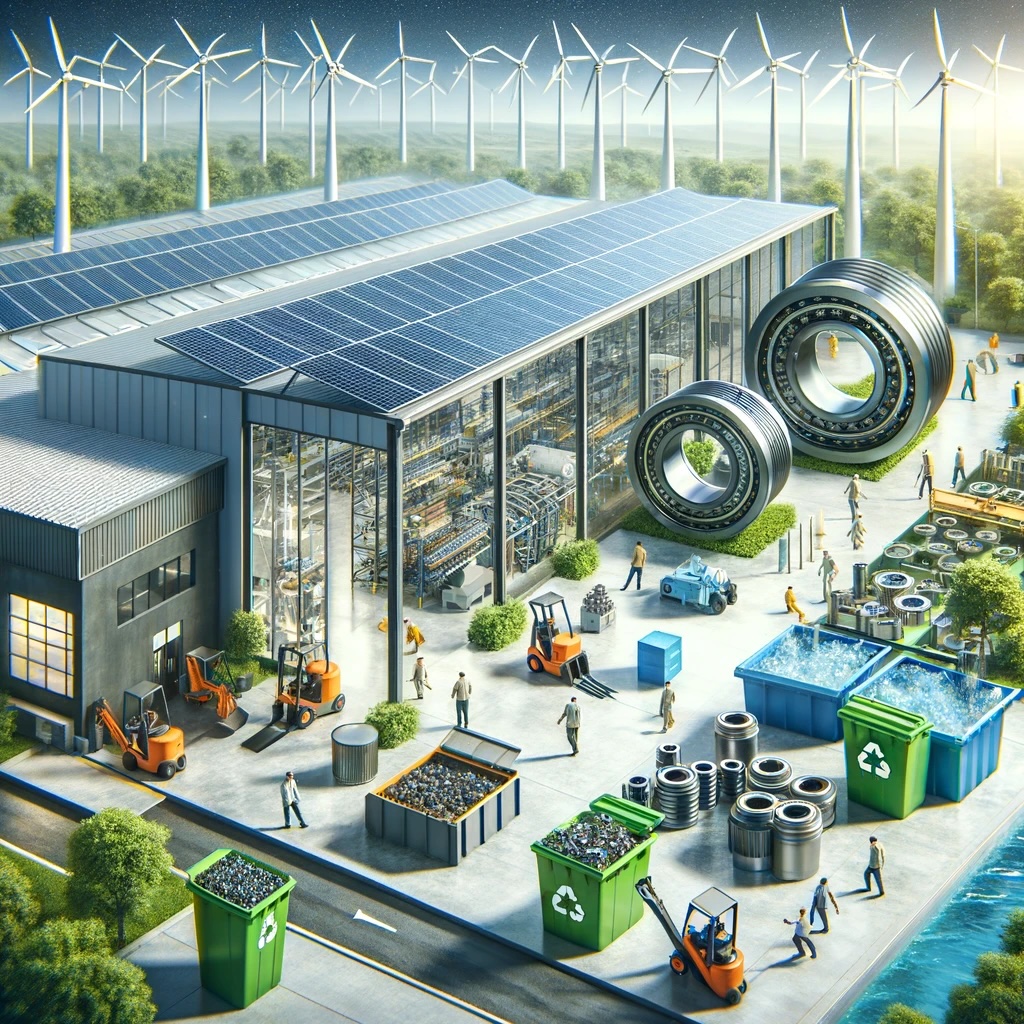

As industries globally move towards sustainability, the bearing industry is also pivoting to greener manufacturing processes and materials. This article explores how the adoption of eco-friendly practices is reshaping bearing production, contributing to environmental conservation without compromising performance. Eco-Friendly MaterialsDiscover the shift towards materials that reduce environmental impact. Biodegradable lubricants and recycled steel are now becoming standard in bearing production, significantly lowering the carbon footprint of these essential components. Energy-Efficient ManufacturingHighlight how bearing manufacturers are op...

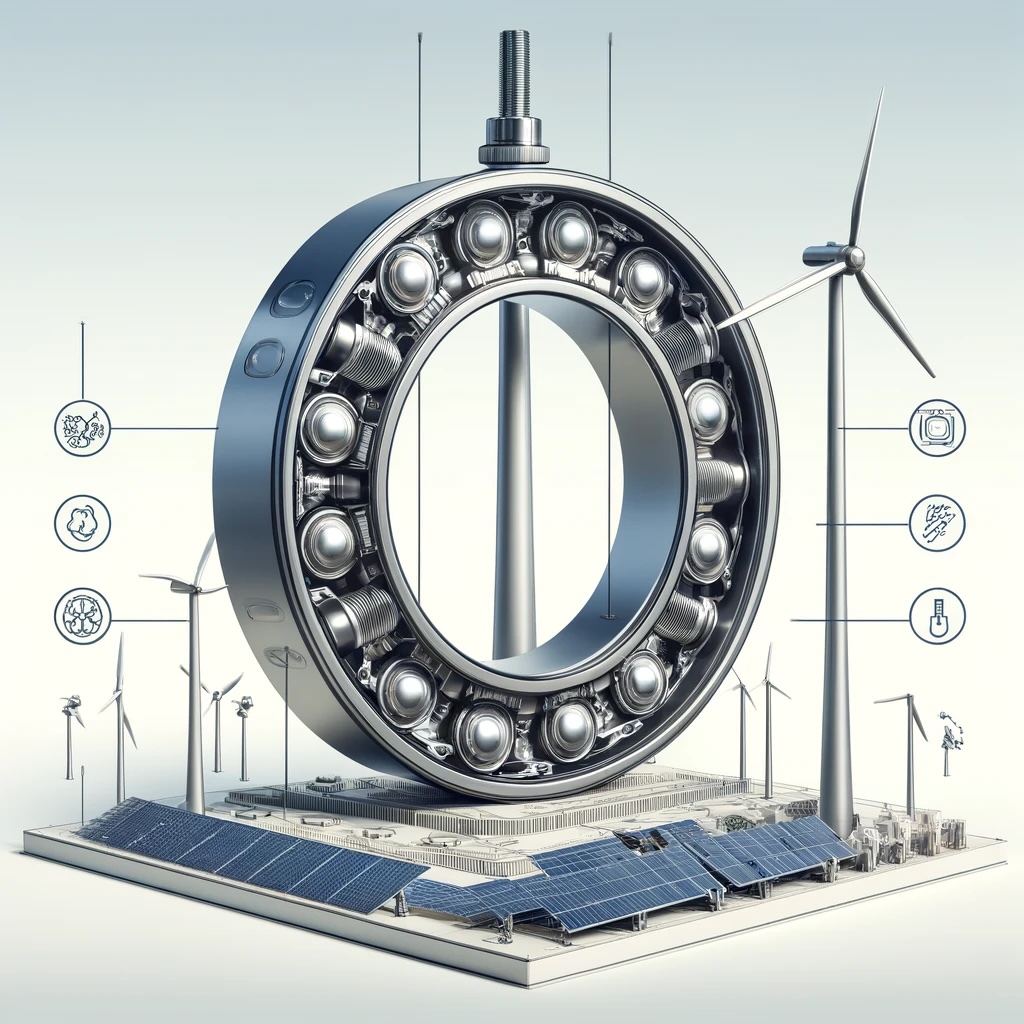

The renewable energy sector is growing rapidly as the world seeks to reduce its carbon footprint and transition to more sustainable energy sources. Bearings play a crucial role in the efficient operation of renewable energy systems, such as wind turbines, solar panels, and hydroelectric generators. This article explores how bearings support these technologies, their unique requirements, and the innovations driving their development. The Role of Bearings in Renewable Energy Systems Wind Turbines: Description: Wind turbines convert kinetic energy from wind into electrical energy. They consist of several rotating components that require...

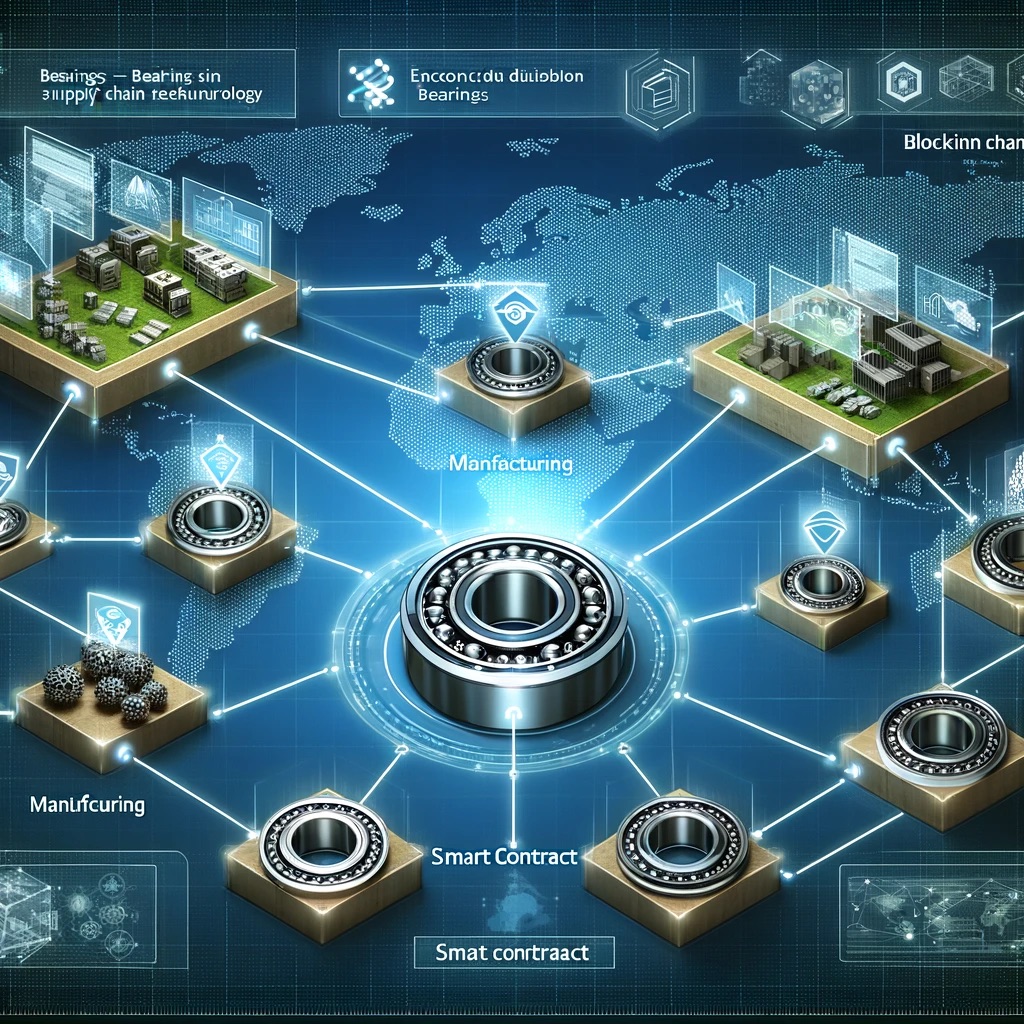

Blockchain technology is revolutionizing many industries by providing enhanced transparency, security, and efficiency, and the bearing industry is no exception. This article delves into how blockchain can transform the supply chain management of bearings, from production to delivery. Introduction to Blockchain in IndustryBriefly explain blockchain technology and its significance in industrial applications, emphasizing its role in ensuring data integrity, traceability, and secure transactions. Traceability and TransparencyDetail how blockchain enables complete traceability of bearings from manufacturing to end-user. This transparency helps i...

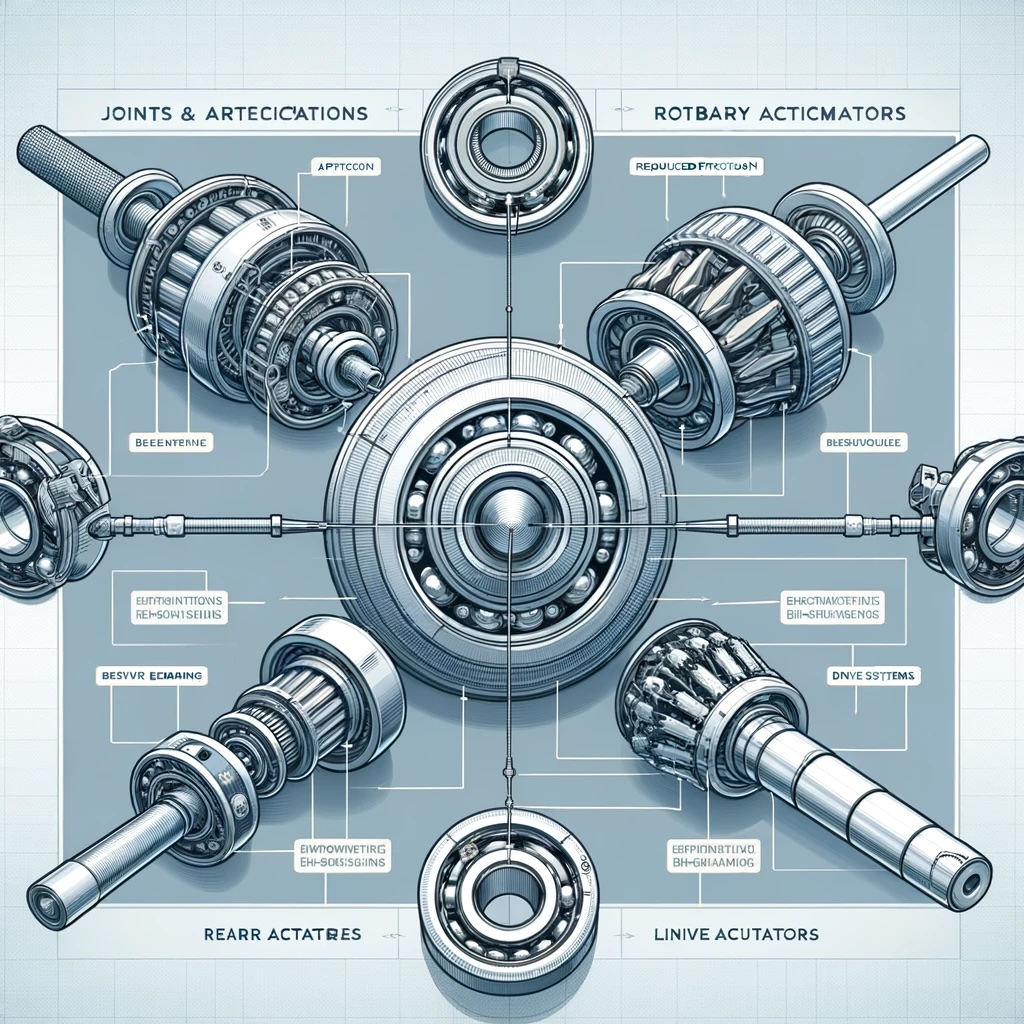

The robotics industry is undergoing a rapid transformation, driven by advances in technology and the increasing demand for automation across various sectors. Bearings, as fundamental components that enable smooth and efficient motion, play a critical role in the development and performance of robotic systems. This article explores how bearings are revolutionizing the robotics industry by enhancing performance, reliability, and precision. The Role of Bearings in Robotics Bearings are used in numerous applications within robotic systems, including: Joints and Articulations: Description: Bearings in robotic joints allow for smooth and ...

In industrial settings, the quality of bearings plays a crucial role in determining the productivity, efficiency, and reliability of machinery. Bearings are fundamental components that reduce friction, support loads, and enable smooth motion in various machines. This article explores how bearing quality impacts industrial productivity and why investing in high-quality bearings is essential for optimal performance and cost savings. Importance of Bearing Quality Reduced Downtime: High-Quality Bearings: High-quality bearings are designed to last longer and withstand harsh operating conditions. This reduces the frequency of bearing repla...

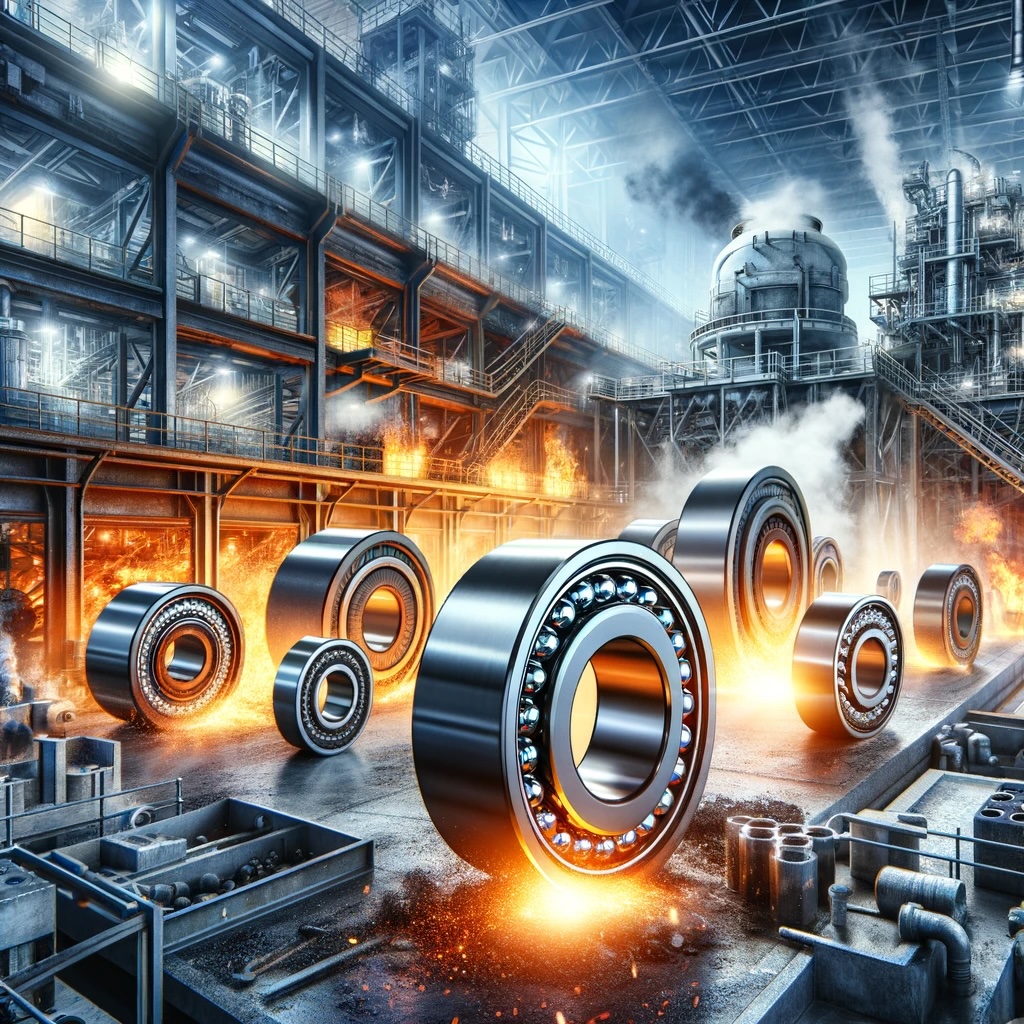

In industries where machinery must operate under extreme conditions—whether due to high temperatures, corrosive substances, or significant load pressures—choosing the right bearings is crucial for operational success and longevity. This guide provides an in-depth look at the considerations necessary when selecting bearings for extreme environments, ensuring your machinery can withstand the toughest conditions without compromise. Understand the ChallengesFirst, identify the specific environmental challenges your bearings will face. Whether it’s high temperatures in metal processing facilities, corrosive chemicals in paper mills, or heavy load...

Bearings are critical components in various machines and systems, ensuring smooth operation and reliability. However, when it comes to extreme environments, standard bearings often face significant challenges. These environments, characterized by high or low temperatures, corrosive conditions, high loads, and high speeds, require specialized bearings designed to withstand these harsh conditions. This article explores the challenges bearings face in extreme environments and the solutions developed to address these issues. Challenges in Extreme Environments High Temperatures: Thermal Expansion: High temperatures can cause bearing mater...

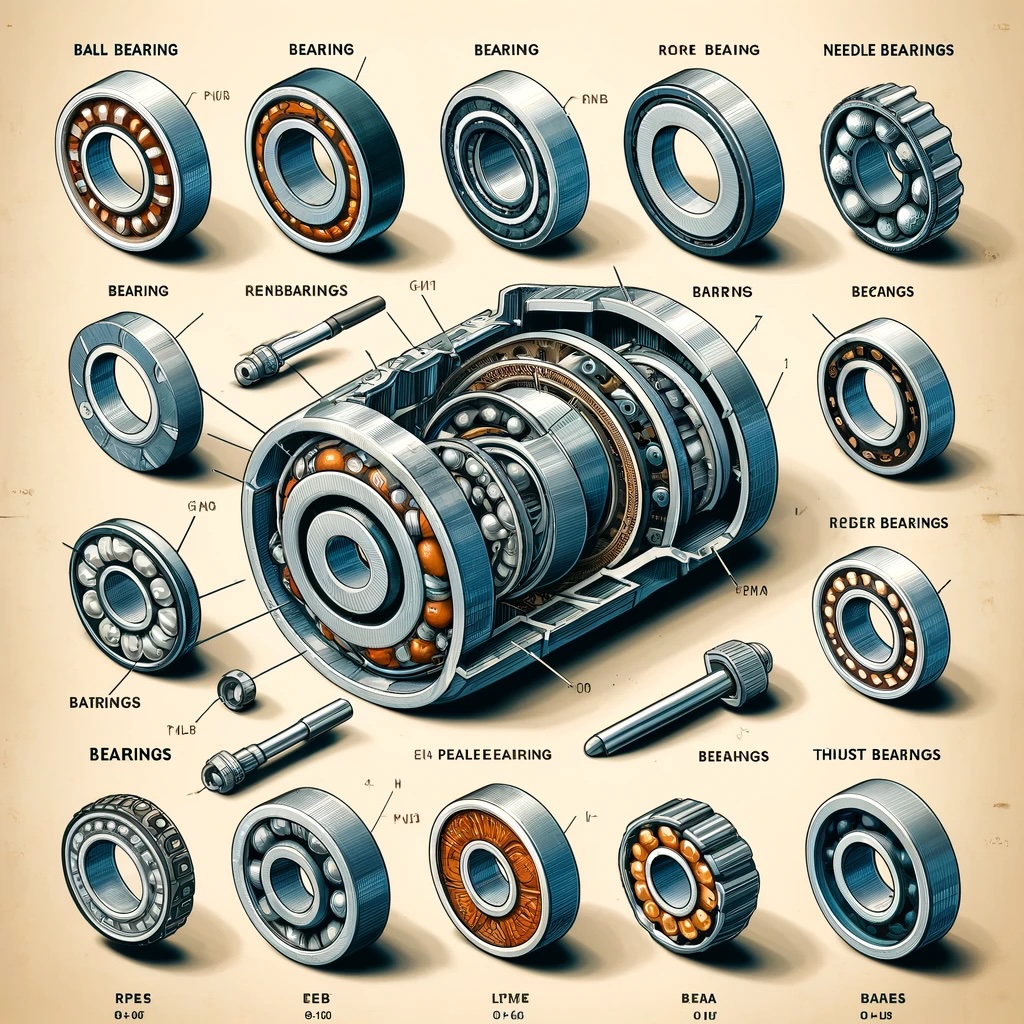

Selecting the right bearing is crucial for ensuring the efficiency and long lifespan of industrial machinery. This guide will provide you with a comprehensive overview of how to choose the best bearings for your industrial applications. 1. Know Your Requirements Before selecting bearings, it's important to carefully specify the requirements of your specific machine or equipment. Consider factors such as speeds, loads, operating environment, and temperature conditions in which the bearing will operate. 2. Types of Bearings There are various types of bearings suitable for industrial applications, including: Ball Bearings: Ideal for appli...

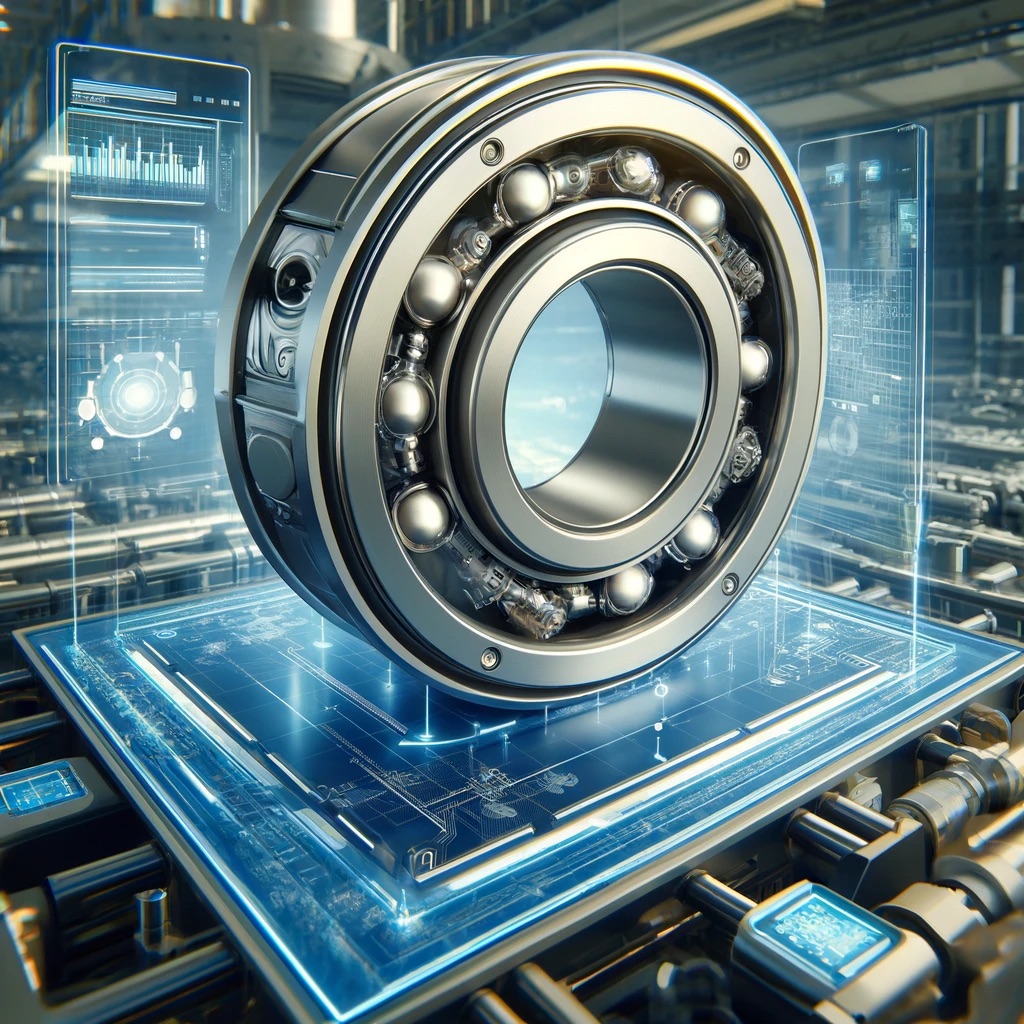

With the advent of Industry 4.0 and an increasing emphasis on automation and data, bearings with integrated sensors are becoming key components for enhancing efficiency and predictive maintenance in many industrial sectors. These intelligent bearings allow real-time monitoring of various parameters, such as vibration, temperature, and pressure, leading to significant improvements in machine performance and safety. Integrated sensors in bearings provide crucial data used for immediate decision-making and process optimization. With this data, companies can anticipate potential issues before they lead to failure, resulting in fewer unplanned do...

Bearings are essential components in many machines and devices, enabling their smooth and efficient operation. There are many types of bearings, each with its own specific characteristics and applications. This article will provide a detailed overview of various types of bearings, including their designs, advantages, and typical uses in industry. Ball Bearings Ball bearings are among the most commonly used types of bearings due to their ability to withstand both radial and axial loads. They consist of a series of spherical balls positioned between two circular grooves on the inner and outer rings. Ball bearings are ideal for applications re...