News and articles, Page 5

List of articles

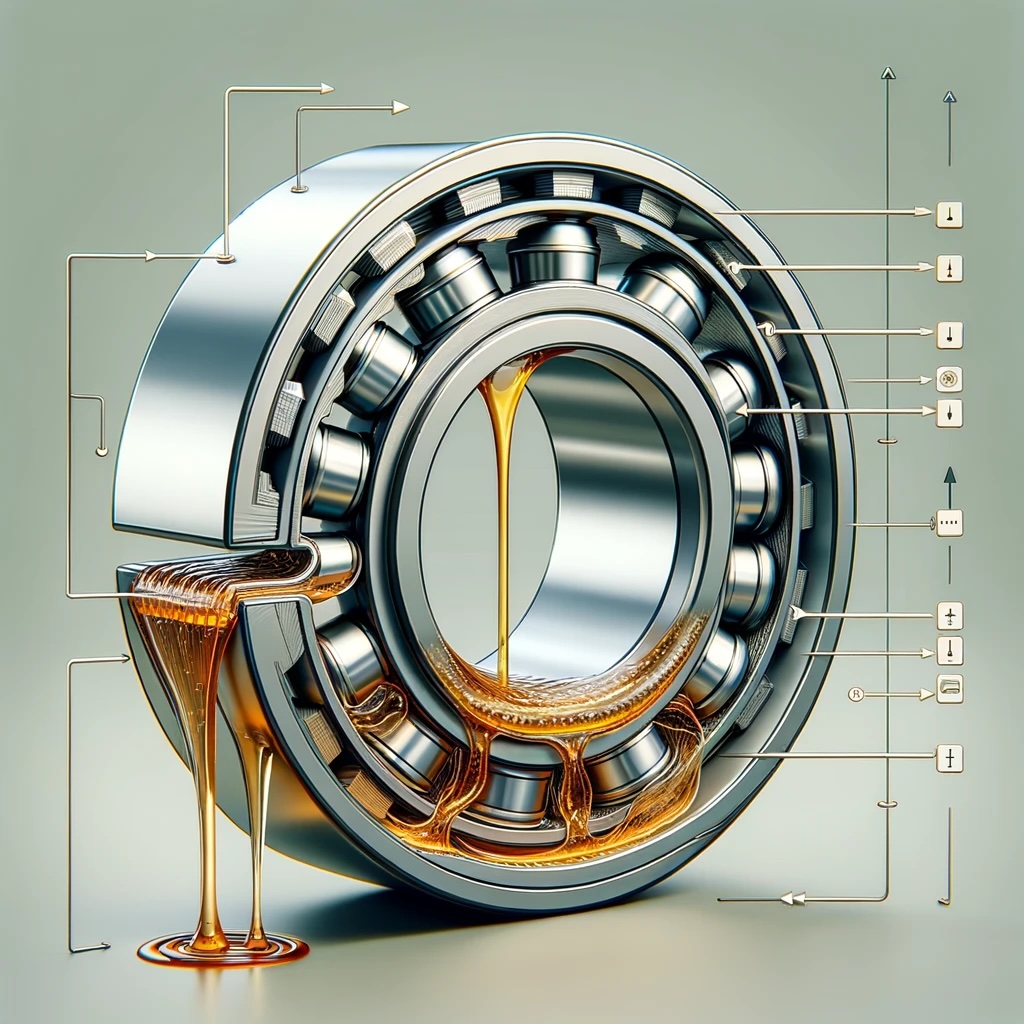

Bearings are critical components in a wide range of machinery, from household appliances to industrial equipment and automotive engines. Their primary function is to reduce friction between moving parts, enabling smooth and efficient operation. However, to maintain their performance and extend their lifespan, proper lubrication is essential. This article explores the significance of lubrication in bearing maintenance and how it can prevent premature failure and costly downtime. Understanding Bearing Lubrication Lubrication involves the application of a lubricant, such as oil or grease, to the bearing surfaces. This creates a thin film that ...

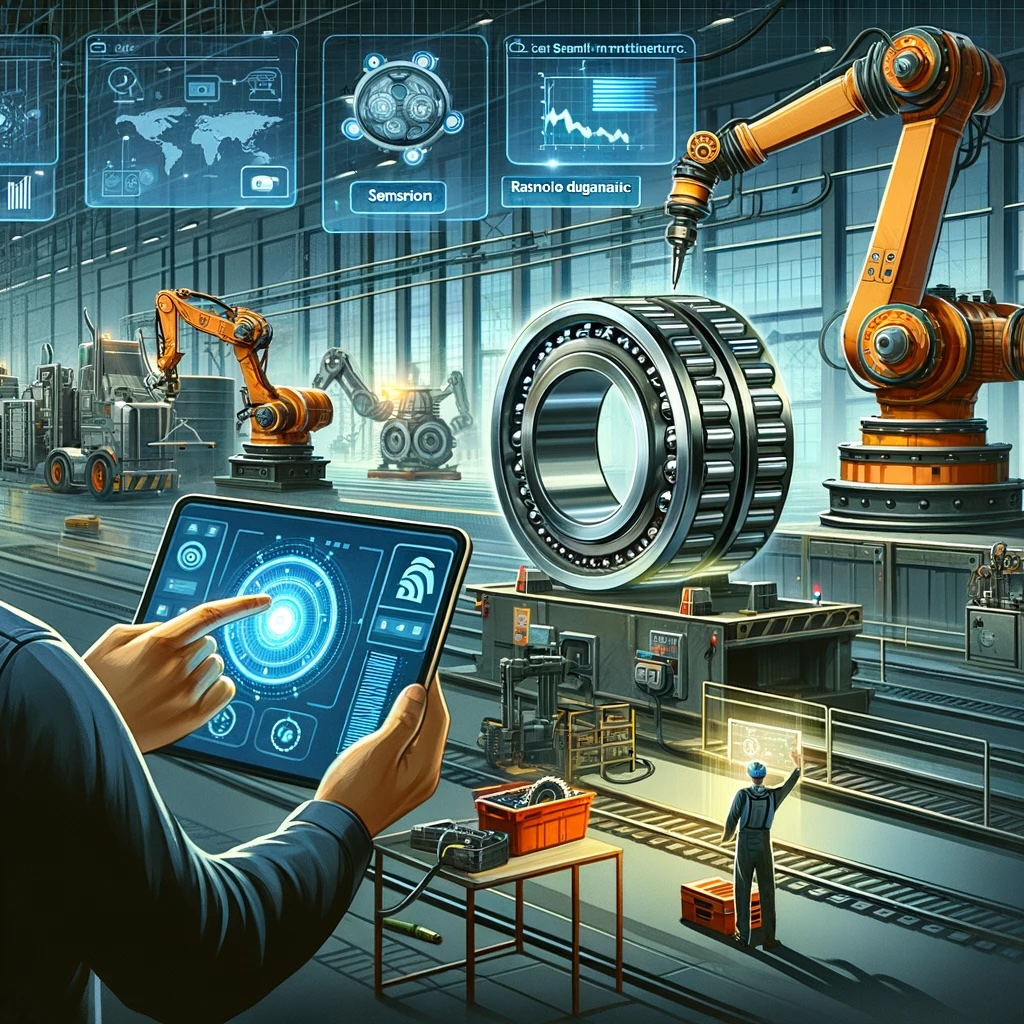

Bearings are key components in most mechanical devices, and their proper maintenance is crucial to ensure long life and efficient operation. In this article, we will look at the importance of regular bearing maintenance and how modern technology is helping to simplify and streamline this process. The Importance of Regular Maintenance Bearings undergo natural wear and tear during operation. Without regular inspection and maintenance, serious issues can arise, such as high temperatures, excessive vibrations, and even equipment failure, which can lead to costly repairs and downtime. Regular maintenance helps identify and address these problems...

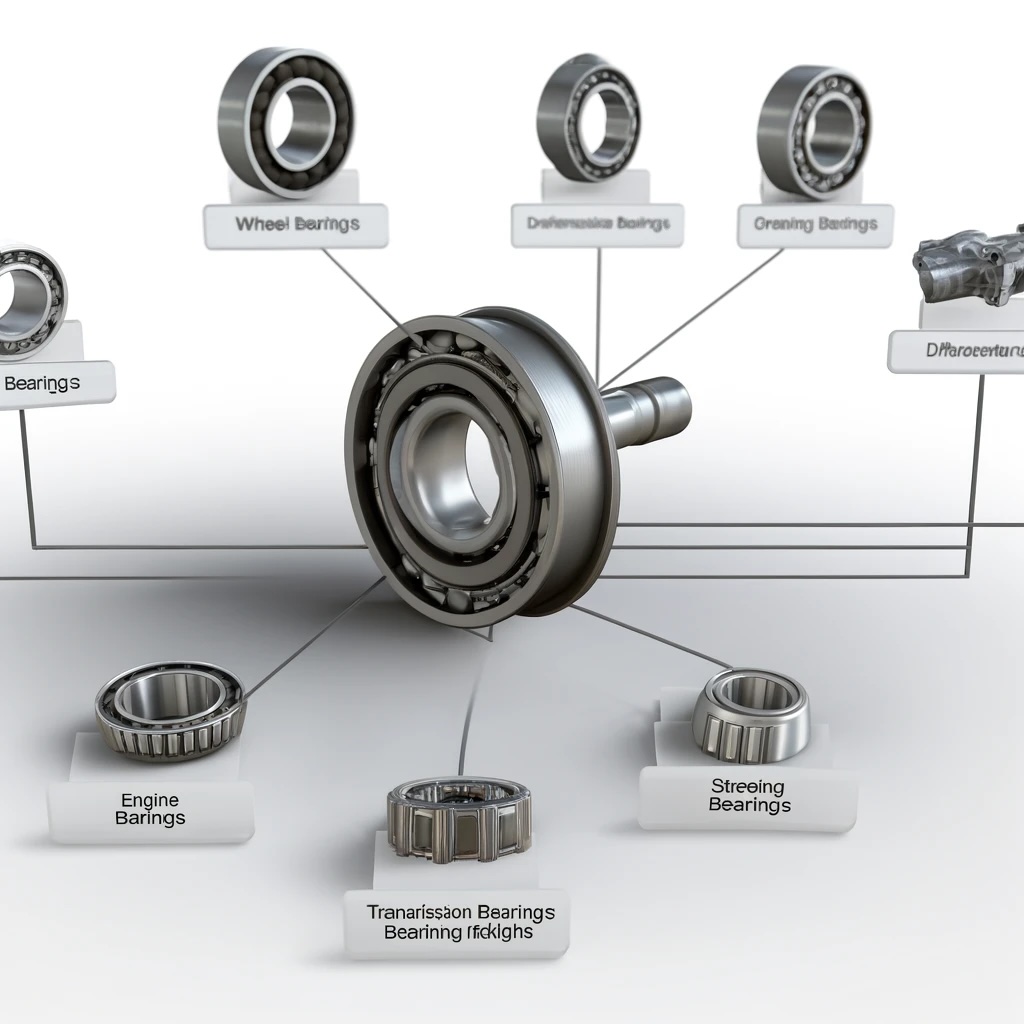

Bearings are vital components in automotive engineering, playing a crucial role in ensuring the smooth operation, reliability, and efficiency of vehicles. From the wheels to the engine, bearings are used in various parts of a car to reduce friction, support loads, and facilitate motion. This article delves into the different types of bearings used in automotive applications and their specific roles in enhancing vehicle performance. Types of Bearings in Automotive Applications Wheel Bearings: Description: Wheel bearings support the vehicle’s weight and allow the wheels to rotate with minimal friction. Applications: Used in the wheel ...

Proper storage of bearings is crucial for maintaining their quality and ensuring maximum lifespan. In this article, we will explore proven methods for storing bearings to protect them from damage, corrosion, and premature wear. 1. Clean and Dry Environment Store bearings in a dry environment with minimal risk of moisture and dust exposure. Moisture can cause corrosion, while dust and contaminants can lead to bearing damage during installation. 2. Temperature Control The storage space should have a stable temperature to prevent condensation, which could cause corrosion. Extreme temperature fluctuations should be minimized. 3. Original Pac...

Bearing installation may seem like a simple task, but even small errors can lead to significant issues in machine operation. In this article, we will look at the ten most common mistakes that occur during bearing installation and ways to prevent these errors. 1. Incorrect Bearing Selection One of the most common mistakes is using the wrong type or size of bearing for a given application. Always ensure the bearing matches the machine specifications and operational requirements. 2. Overlooking Shaft and Bearing Seat Condition Before installation, it is essential to check the shaft and bearing seat for damage or wear. Any damage can lead to ...

Bearing installation may seem like a simple task, but even small errors can lead to significant issues in machine operation. In this article, we will look at the ten most common mistakes that occur during bearing installation and ways to prevent these errors. 1. Incorrect Bearing Selection One of the most common mistakes is using the wrong type or size of bearing for a given application. Always ensure the bearing matches the machine specifications and operational requirements. 2. Overlooking Shaft and Bearing Seat Condition Before installation, it is essential to check the shaft and bearing seat for damage or wear. Any damage can lead to ...

Bearings are a crucial component of nearly every moving machine or device. From automobiles and industrial machinery to household appliances and medical equipment, bearings reduce friction between moving parts, increase efficiency, and prolong the life of equipment. However, there are many different types of bearings, each with its own specific characteristics and uses. In this article, we'll look at the main types of bearings, their characteristics, and specific applications. Ball Bearings Ball bearings are the most common type of bearings and are suitable for a wide range of applications. They consist of a metal ring with balls moving fre...

Bearings and transmission technologies are fundamental building blocks for a wide range of industrial, automotive, and engineering applications. These components play a crucial role in the efficiency, reliability, and performance of the systems in which they are used. In recent years, significant innovations in this field have focused on improving performance, reducing friction, extending lifespan, and increasing sustainability. Here's an overview of some of the latest trends and enhancements in bearings and transmission technologies. Material Innovations One of the main directions of innovation is the development and use of new materials t...

Bearings are a crucial component in a wide range of mechanical applications, from automobiles to industrial machinery. The quality of bearings can significantly impact the performance and lifespan of your equipment. In this article, we'll look at five main reasons why you should choose high-quality bearings. 1. Longer Equipment Lifespan High-quality bearings are designed to withstand extreme loads and operating conditions, meaning your equipment will have a longer lifespan and higher reliability. Investing in quality bearings quickly pays off by reducing repair and replacement costs. 2. Increased Efficiency and Performance Higher-quality ...

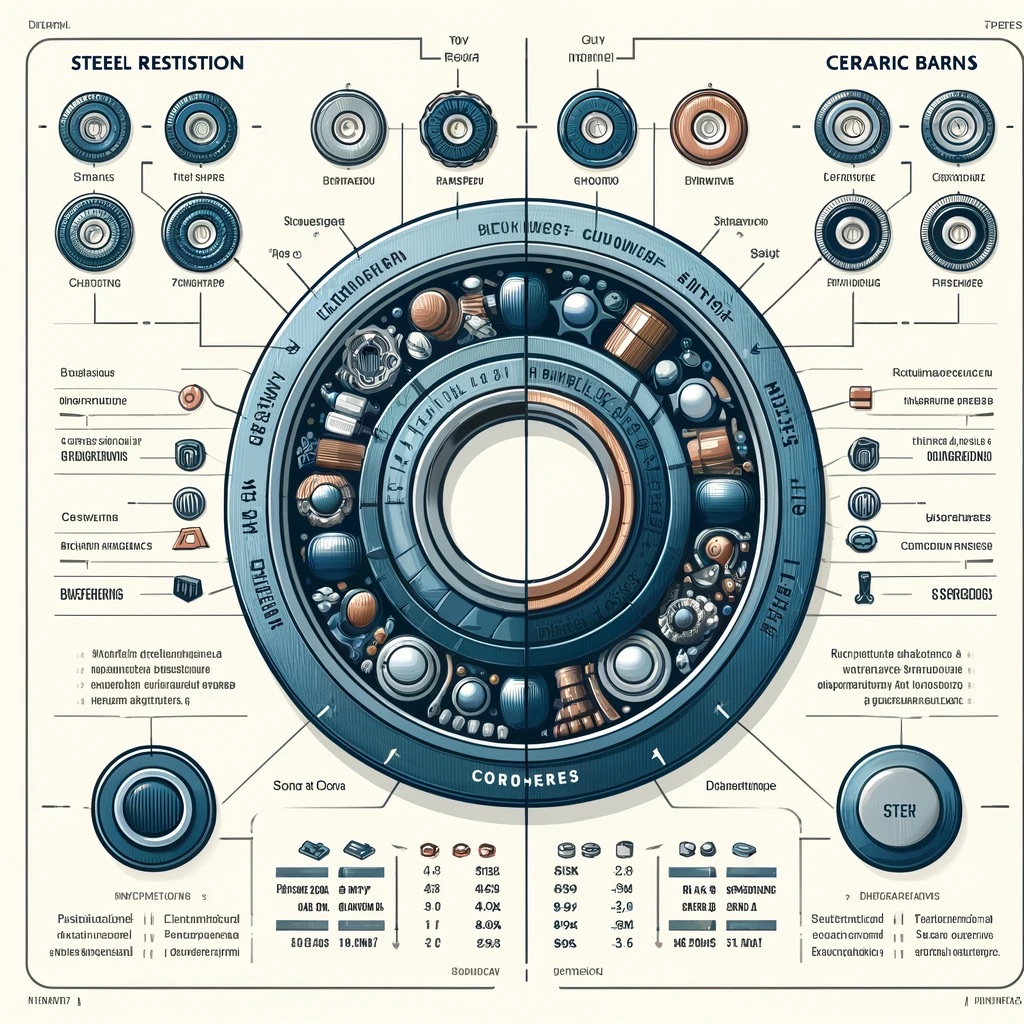

The choice of bearing material can significantly affect its performance, lifespan, and applications. In this article, we will focus on comparing two popular materials for bearing production: steel and ceramic. We will explore their advantages, disadvantages, and ideal uses. 1. Steel Bearings Advantages: High Strength and Durability: Steel is an extremely strong material, making it an ideal choice for high-load applications. Lower Cost: Steel bearings are typically cheaper than ceramic ones, making them more accessible for a wide range of applications. Disadvantages: Susceptibility to Corrosion: Without adequate treatment or protec...